News

Stretch film machine needs good maintenance

Stretch film machine needs good maintenance

We need to maintain stretch film machine every day. For this purpose, we need to know the following knowledge.

1, the power, vacuum system, air pressure system and cooling system should be checked before the start of the machine, and the rotation of each rotating part should be checked correctly after the equipment is started, and the lubrication of each lubricating part should be checked carefully, and the electrical and instrument should be maintained and maintained in accordance with the regulations.

2, assign special operation to stretch film machine, do not allow the extruder screw to be idle without material, so as not to scratch the screw and barrel. When the machine is shut down, if there is storage in the cylinder, the temperature of each temperature zone must be raised to the requirements according to the requirements of the process before the machine is opened again, and the thermal insulation can be opened for more than 30 minutes, and the temperature is strictly prohibited before the request is reached, so as to avoid damage to the machine parts.

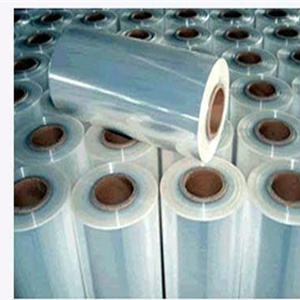

STRETCH FILM FACTORY

3, when feeding the stretch film machine hopper, it is necessary to ensure clean, strictly prevent the entry of metallic debris, sand and small tools, so as to prevent the damage of the machine barrel and screw. If abnormal sound is found in the operation, it should be stopped immediately.

4, stretch film machine screw removed from the machine tube, should be properly handled to prevent deformation. If the screw is not installed in the barrel for a long time, the screw must be hung vertically to prevent injury, bending and permanent deformation, and the surface of the cylinder and screw is coated with antirust oil for protection.

5, the use, adjustment, maintenance and maintenance of temperature control instruments, electronic instruments and electrical switches should be carried out according to the stretch film machine regulations and product instructions.

6, in addition to daily maintenance, we should make regular maintenance, clean the die head once every three months, replace the grease every three months for various bearings, replace the lubricating oil every half year to the reducer, and make a major repair to the whole equipment every two years.